Dr Victor Porcupine Bezoar Powder Production Process

Dr Victor Porcupine Bezoar's herbal products are manufactured in accordance with the strictest GMP standards. Similarly, the production process of Dr Victor Porcupine Bezoar also applies the same GMP procedures and standards.

1. Micro-Weighing

2. Technical Cutting

3. Hand-Grinding

4. Removing Impurities

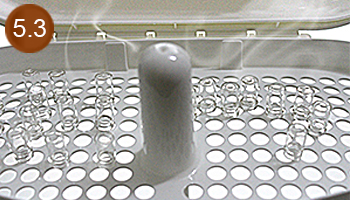

5. Disinfection Procedure

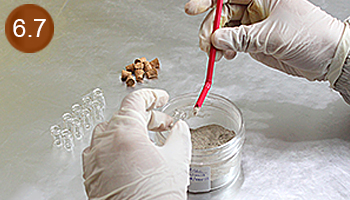

6. Aseptic Bottling

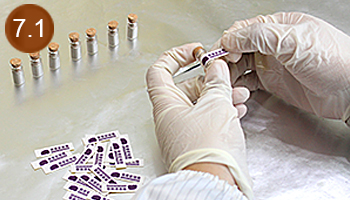

7. Brand Labelling

8. Printing Production Date

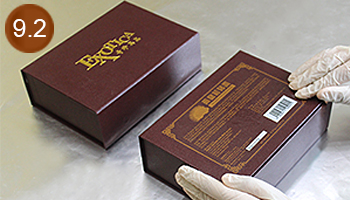

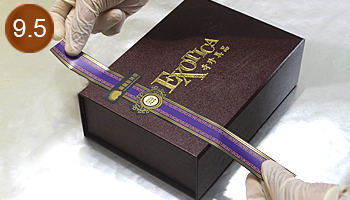

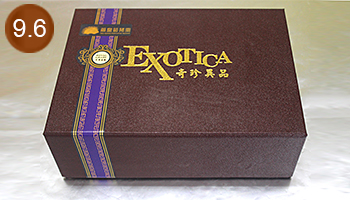

9. Box Labeling and Final Packaging

Frequently Asked Questions

1. What are the advantages of hand-grinding compared to machine-grinding ? Why does Dr Victor insist on using traditional methods?

Answer: Hand-grinding preserves the natural quality, active ingredients, and medicinal effects of the porcupine fruit better than machine-grinding, which can damage the active ingredients due to high temperatures. Furthermore, hand-grinding allows for more meticulous removal of impurities such as small stones, porcupine hair, spines, and weeds, ensuring the purity and safety of the product.

2. What are the steps in the impurity removal process? How does it affect the quality of the porcupine fruit ?

Answer: Removing impurities is crucial to ensuring the purity and high quality of the porcupine fruit. We use sieves and tweezers to carefully remove small stones, porcupine hair, spines, and weeds that may affect efficacy or safety. This process guarantees the product's medicinal value and purity, and ensures that consumers receive a safe, high-quality, and reliable product that is worth the price.

For the complete list of frequently asked questions, please click